Understanding Toolpaths in IRBCAM

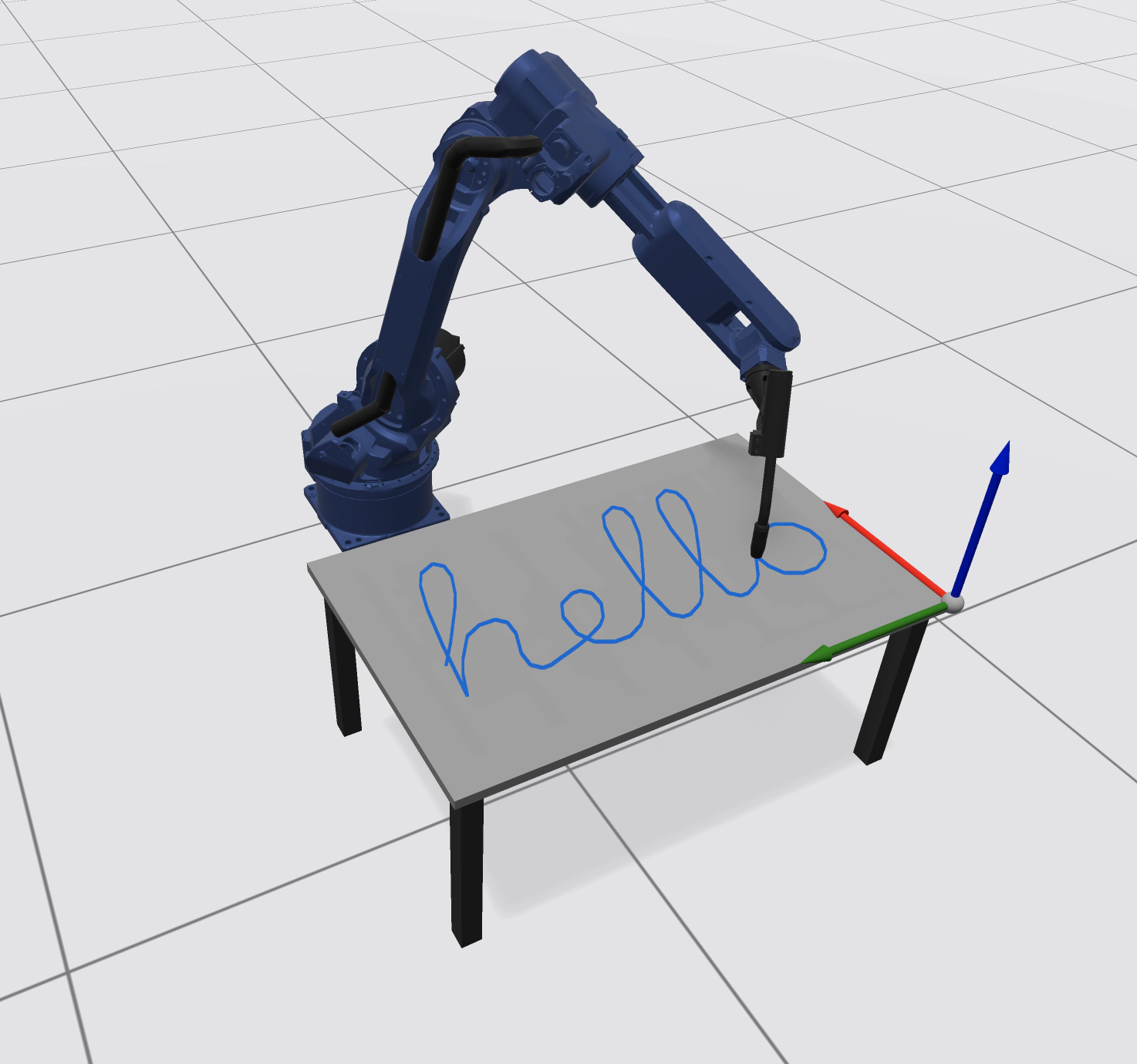

A toolpath is a pre-defined route or sequence that a tool follows to perform a specific task, such as cutting, welding, painting, or assembling. In other words, a toolpath describes the motion of your tool in space and, in term, the work you want to do. A toolpath can be simple, such as a straight line in space or complex, such as a continuous 5-axis machining operation.

Typically, a toolpath is not initially defined relative to the robot, but rather to a local reference like the corner of a table. In IRBCAM you can move the toolpath to make it fit into your work station and robot’s reachability.

Creating Toolpaths in IRBCAM

In IRBCAM, you can create toolpaths through three different methods, each catering to different user needs and workflows:

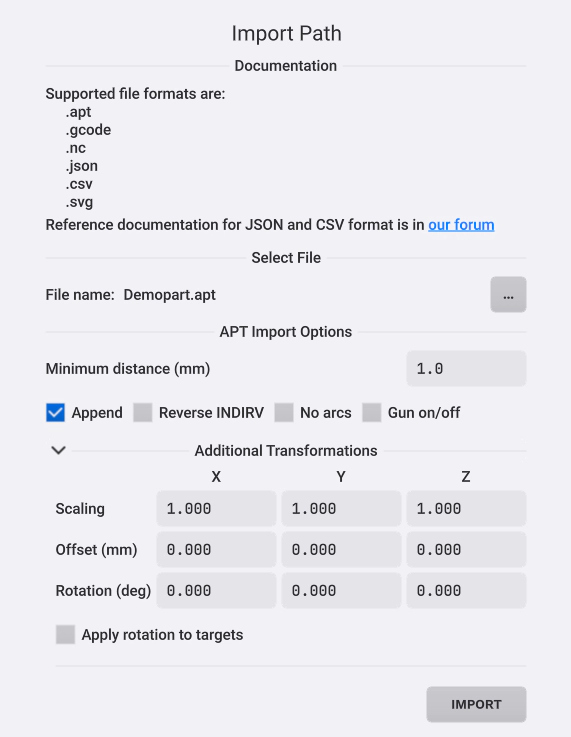

Importing an APT File from CAM Software

The APT (Automatically Programmed Tool) format is a high-level programming language used to describe toolpaths. Historically, CNC machinists programmed machines directly using APT, however nowadays it is mostly used as an exchange format. Most CAM (Computer-Aided Manufacturing) softwares support exporting toolpaths in APT format.

- Benefits:

- Seamless Integration: Easily transition from CAM software to IRBCAM.

- Manage Complexity: Using CAM to create toolpaths makes it easier to handle complicated operations.

- Accuracy: Retains the exact specifications and precision from the CAM-generated toolpath.

Importing JSON or CSV Files

If you already have toolpath data in a structured format, such as JSON or CSV, IRBCAM allows you to import this data to create toolpaths.

- Benefits:

- Full Control: Set all targets explicitly. You are in full control of every aspect of the toolpath.

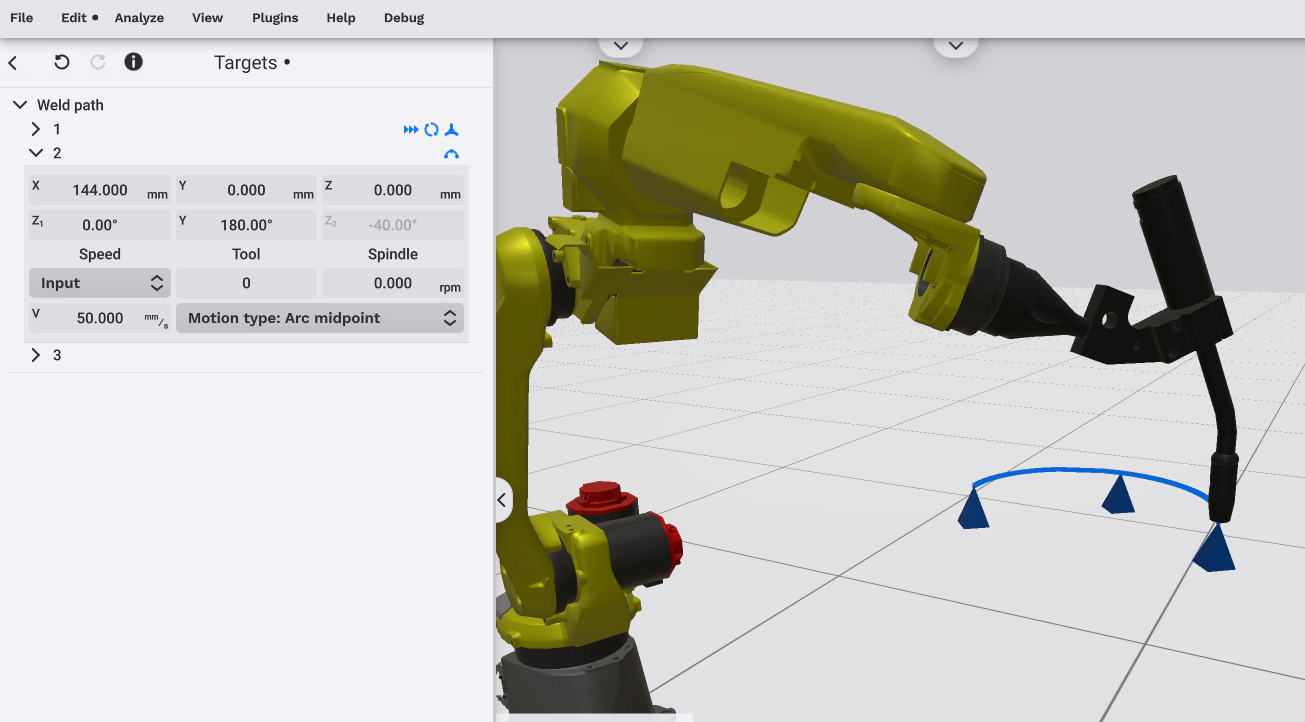

Manually Setting Up the Toolpath in IRBCAM

In addition to importing, IRBCAM offers a hands-on interface to manually set up and edit toolpaths.

- Benefits:

- Fast: For simple toolpaths, it is incredibly fast to set up your path.

- Visual: You can see where your target is in relation to your robot at any time.

- Real-Time Feedback: See if the robot can reach all your targets while you edit your path.

Conclusion

IRBCAM offers multiple ways to create toolpaths, catering to users with different levels of expertise and varying project requirements. Whether you’re importing complex paths from CAM software, utilizing structured data files, or building from the ground up, IRBCAM provides the tools you need to get your robot moving efficiently and accurately. You might want to check out our video tutorials.